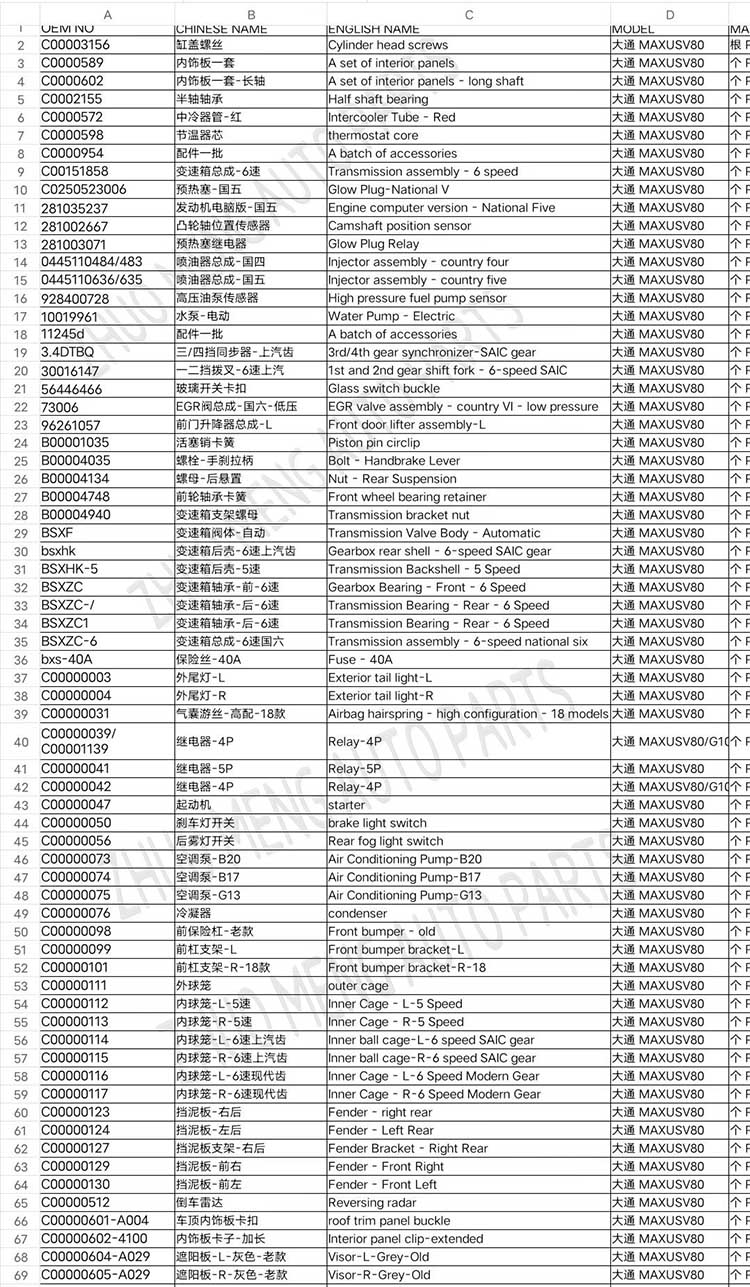

SAIC MAXUS V80 C0006106 Air Conditioning Pipe - Evaporator ho Compressor

Tlhaloso e Khutšoanyane:

Lintlha tsa Sehlahisoa

Li-tag tsa Sehlahisoa

Lintlha tsa lihlahisoa

| Lebitso la lihlahisoa | Pipe ea ho Felisa Moea - Evaporator ho Compressor |

| Tšebeliso ea lihlahisoa | SAIC MAXUS V80 |

| Lihlahisoa OEM NO | C0006106 |

| Org ea sebaka | E ENTSOE CHAENA |

| Brand | CSSOT /RMOEM/ORG/COPY |

| Lead time | Stock, haeba e ka tlase ho 20 PCS, e tloaelehileng khoeli e le 'ngoe |

| Tefo | TT depositi |

| Khampani Brand | CSSOT |

| Sistimi ea kopo | Sistimi e bonolo |

Tsebo ea lihlahisoa

Mochine o futhumatsang moea oa likoloi ke pelo ea mochini oa sehatsetsi sa moea oa likoloi 'me o bapala karolo ea ho hatella le ho tsamaisa mouoane oa sehatsetsing. Ho na le mefuta e 'meli ea li-compressor: phalliso e sa fetoheng le phallo e fapaneng. Ho latela melao-motheo e fapaneng ea ts'ebetso, li-compressor tsa moea li ka aroloa ka li-compressor tse sa fetoheng le li-compressor tse fapaneng tsa phallo.

Ho latela mekhoa e fapaneng ea ho sebetsa, li-compressor ka kakaretso li ka aroloa ka mefuta e khutlisang le ea rotary. Li-compressor tse tloaelehileng li kenyelletsa mofuta oa molamu o kopanyang oa crankshaft le mofuta oa axial piston, 'me li-compressor tse tloaelehileng tsa rotary li kenyelletsa mofuta oa rotary vane le mofuta oa moqolo.

Mochine o futhumatsang moea oa likoloi ke pelo ea mochini oa sehatsetsi sa moea oa likoloi 'me o bapala karolo ea ho hatella le ho tsamaisa mouoane oa sehatsetsing.

Karolelano

Li-compressor li arotsoe ka mefuta e 'meli: phalliso e sa fetoheng le phallo e fapaneng.

Li-compressor tsa moea hangata li arotsoe ka mefuta e tšoanang le ea rotary ho latela mekhoa ea tsona ea ka hare ea ho sebetsa.

Ho sebetsa molao-motheo editing kgaso

Ho latela melao-motheo e fapaneng ea ts'ebetso, li-compressor tsa moea li ka aroloa ka li-compressor tse sa fetoheng le li-compressor tse fapaneng tsa phallo.

Compressor e tsitsitseng e tsitsitseng

Ho falla ha compressor e tsitsitseng-displacement ho eketseha ka ho lekana le keketseho ea lebelo la enjene. E ke ke ea fetola tlhahiso ea matla ka bo eona ho latela tlhoko ea ho pholisa, 'me e na le phello e batlang e le kholo tšebelisong ea mafura a enjene. Taolo ea eona ka kakaretso e bokella lets'oao la mocheso la sets'oants'o sa moea sa mouoane. Ha mocheso o fihla mocheso o behiloeng, clutch ea electromagnetic ea compressor ea lokolloa 'me compressor e khaotsa ho sebetsa. Ha mocheso o phahama, clutch ea electromagnetic e sebetsa 'me compressor e qala ho sebetsa. Compressor e tsitsitseng ea ho falla e boetse e laoloa ke khatello ea tsamaiso ea moea. Ha khatello ea pipeline e phahame haholo, compressor e khaotsa ho sebetsa.

Compressor e feto-fetohang ea moea o futhumatsang moea

Compressor e feto-fetohang e ka fetola tlhahiso ea matla ka bo eona ho latela mocheso o behiloeng. Sistimi ea taolo ea boemo ba moea ha e bokelle lets'oao la mocheso oa sets'oants'o sa moea sa mouoane, empa e laola tekanyo ea khatello ea compressor ho latela lets'oao la phetoho ea khatello e phaepheng ea moea e fetolang mocheso oa moea ka bo eona. Nakong eohle ea sehatsetsing, compressor e lula e sebetsa, 'me phetoho ea matla a sehatsetsing e laoloa ka ho feletseng ke valve e laolang khatello e kentsoeng ka har'a compressor. Ha khatello e pheletsong ea phaephe ea moea o pholisa moea e phahame haholo, valve e laolang khatello e khutsufatsa sekhahla sa piston ka har'a compressor ho fokotsa sekhahla sa khatello, se tla fokotsa matla a sehatsetsi. Ha khatello e qetellong ea khatello e phahameng e theohela boemong bo itseng 'me khatello e qetellong ea khatello e tlaase e nyolohela boemong bo itseng, valve e laolang khatello e eketsa sekhahla sa piston ho ntlafatsa matla a sehatsetsing.

Khethollo ea mokhoa oa mosebetsi

Ho latela mekhoa e fapaneng ea ho sebetsa, li-compressor ka kakaretso li ka aroloa ka mefuta e khutlisang le ea rotary. Li-compressor tse tloaelehileng li kenyelletsa mofuta oa molamu o kopanyang oa crankshaft le mofuta oa axial piston, 'me li-compressor tse tloaelehileng tsa rotary li kenyelletsa mofuta oa rotary vane le mofuta oa moqolo.

Crankshaft e kopanyang molamu oa compressor

Ts'ebetso ea compressor ena e ka aroloa ka tse 'ne, e leng compression, exhaust, atoloso, suction. Ha crankshaft e potoloha, molamu o kopanyang o khanna piston hore e khutlisetsoe, 'me molumo o sebetsang o entsoeng ka lerako le ka hare la cylinder, hlooho ea cylinder le karolo e ka holimo ea piston e fetoha nako le nako, kahoo e hatella le ho tsamaisa sehatsetsi tsamaisong ea sehatsetsing. The crankshaft connecting rod compressor ke moloko oa pele oa compressor. E sebelisoa haholo, e na le theknoloji e tsoetseng pele ea tlhahiso, sebopeho se bonolo, litlhoko tse tlase ho lisebelisoa tsa ho sebetsa le theknoloji ea ho sebetsa, le litšenyehelo tse tlaase. E na le matla a ho ikamahanya le maemo, e khona ho ikamahanya le maemo a mangata a khatello le litlhoko tsa matla a sehatsetsing, 'me e na le ts'ebetso e matla ea ho boloka.

Leha ho le joalo, "crankshaft connecting rod compressor" e boetse e na le mefokolo e totobetseng, e kang ho se khone ho finyella lebelo le phahameng, mochine o moholo ebile o boima, 'me ha ho bonolo ho finyella boima bo bobebe. Mokelikeli ha o tsoele pele, phallo ea moea e atisa ho fetoha, 'me ho na le ho sisinyeha ho hoholo nakong ea ts'ebetso.

Ka lebaka la litšoaneleho tse ka holimo tsa li-compressor tsa crankshaft-connecting-rod, li-compressor tse nyenyane tse fokolang li amohetse sebopeho sena. Hajoale, li-compressor tsa crankshaft-connecting-rod li sebelisoa haholo lits'ebetsong tse kholo tse tsamaisang moea bakeng sa likoloi tsa baeti le literaka.

Axial Piston Compressor

Li-compressor tsa Axial piston li ka bitsoa li-compressor tsa moloko oa bobeli, 'me tse tloaelehileng ke li-rocker-plate kapa li-swash-plate compressors, e leng lihlahisoa tse tloaelehileng ho li-compressor air-conditioning tsa likoloi. Likarolo tse kholo tsa compressor ea poleiti ea swash ke shaft e kholo le poleiti ea swash. Li-cylinders li hlophisitsoe ka mokhoa o pota-potileng le shaft e ka sehloohong ea compressor e le setsi, 'me tataiso ea motsamao oa piston e bapa le moqomo o ka sehloohong oa compressor. Lipiston tsa li-compressor tsa poleiti tse ngata li entsoe joalo ka lipiston tse nang le lihlooho tse peli, joalo ka li-axial 6-cylinder compressor, li-cylinders tse 3 li ka pele ho komporo, 'me lisilindara tse ling tse 3 li ka morao ho komporo. Lipiston tsa lihlooho tse peli li thella ka tandem ho lisilindara tse fapaneng. Ha ntlha e 'ngoe ea piston e hatella mouoane oa sehatsetsi ka silindara e ka pele, ntlha e 'ngoe ea piston e hula mouoane oa sehatsetsi ka moqomong o ka morao. Silinda e 'ngoe le e' ngoe e na le li-valve tsa moea tse phahameng le tse tlase, 'me phala e' ngoe e matla e sebelisoa ho hokahanya likamore tse ka pele le tse ka morao tsa khatello e phahameng. Letlapa le sekametseng le tsitsitsoe ka molamu o ka sehloohong oa konpressor, moeli oa poleiti e sekametseng e bokelloa ka har'a groove bohareng ba piston, 'me groove ea piston le bohale ba poleiti e sekametseng li tšehetsoa ke libere tsa bolo ea tšepe. Ha shaft e kholo e potoloha, poleiti ea swash e boetse e potoloha, 'me ntlha ea sesepa e sutumelletsa piston hore e khutlisetse axially. Haeba poleiti ea swash e potoloha hanngoe, piston e ka pele le e ka morao e 'ngoe le e 'ngoe e tlatsa potoloho ea ho hatella, ho ntša metsi, ho atolosa le ho hula, e leng ntho e lekanang le mosebetsi oa li-cylinders tse peli. Haeba e le axial 6-cylinder compressor, li-cylinders tse 3 le lipiston tse 3 tse nang le lihlooho tse peli li ajoa ka ho lekana karolong ea cylinder block. Ha shaft e kholo e potoloha hang, e lekana le phello ea li-cylinders tse 6.

The swash plate compressor e batla e le bonolo ho finyella miniaturization le boima bo bobebe, 'me e ka finyella ts'ebetso e phahameng ka potlako. E na le sebopeho sa compact, ts'ebetso e phahameng le ts'ebetso e tšepahalang. Kamora ho hlokomela taolo e fapaneng ea phalliso, e sebelisoa haholo ho li-air conditioner tsa koloi.

Compressor ea Rotary Vane

Ho na le mefuta e 'meli ea libopeho tsa cylinder bakeng sa li-compressor tsa rotary vane: chitja le oval. Ka cylinder e chitja, molamu o ka sehloohong oa rotor o na le sebaka se lekaneng ho tloha bohareng ba cylinder, e le hore rotor e khomarele haufi-ufi pakeng tsa masoba a ho hula le a ho qeta ka holim'a sefahleho se ka hare sa silinda. Ka cylinder ea elliptical, axis e kholo ea rotor le bohareng ba ellipse lia lumellana. Li-blades tsa rotor li arola silinda ka libaka tse 'maloa. Ha shaft e ka sehloohong e khanna rotor ho potoloha hanngoe, molumo oa libaka tsena o fetoha ka ho tsoelang pele, 'me mouoane oa sehatsetsing o boetse o fetoha ka molumo le mocheso libakeng tsena. Li-compressor tsa Rotary vane ha li na valve ea ho hula hobane li-vanes li etsa mosebetsi oa ho monya le ho hatella sehatsetsing. Haeba ho na le li-blades tse 2, ho na le mekhoa e 2 ea ho qeta ho potoloha e le 'ngoe ea shaft e kholo. Ha li-blades li ntse li le ngata, ho fokotseha ha khatello ea compressor ho fokotseha.

Joalo ka kompressor ea moloko oa boraro, hobane bophahamo le boima ba "rotary vane compressor" bo ka fokotsoa, ho bonolo ho hlophisoa ka phaposi ea enjene e moqotetsane, hammoho le melemo ea molumo o tlase le ho thothomela, le ts'ebetso e phahameng ea volumetric, e boetse e sebelisoa lits'ebetsong tsa moea tsa likoloi. ke fumane kopo. Leha ho le joalo, rotary vane compressor e na le litlhoko tse phahameng mabapi le ho nepahala ha mochini le litšenyehelo tse phahameng tsa tlhahiso.

penya compressor

Li-compressor tse joalo li ka bitsoa li-compressor tsa moloko oa 4. Sebopeho sa li-scroll compressors li arotsoe haholo ka mefuta e 'meli: mofuta o matla le o tsitsitseng le mofuta oa phetoho e habeli. Hona joale, mofuta o matla le o tsitsitseng ke oona o sebelisoang ka ho fetisisa. Likarolo tsa eona tse sebetsang haholo-holo li entsoe ka turbine e matla le turbine e tsitsitseng. Mehaho ea li-turbine tse matla le tse tsitsitseng li ts'oana haholo, 'me ka bobeli li entsoe ka poleiti ea ho qetela le leino la spiral le tlohang karolong ea ho qetela, tse peli li hlophisitsoe ka mokhoa o ts'oanang 'me phapang ke 180 °, turbine e tsitsitseng e eme,' me turbine e tsamaeang e pota-potiloe ka mokhoa o ts'oanelang 'me e fetoleloa ka tlas'a mochine o khethehileng, o fetoleloa ka tlas'a mochine o khethehileng. ha ho na ho potoloha, ke phetohelo feela. Li-compressor tsa moqolo li na le melemo e mengata. Ka mohlala, compressor e nyenyane ka boholo le boima ba 'mele bo bobebe,' me lesela la eccentric le tsamaisang motsamao oa turbine le ka potoloha ka lebelo le phahameng. Hobane ha ho na valve ea ho hula le valve ea ho ntša metsi, mochine oa compressor o sebetsa ka botšepehi, 'me ho bonolo ho lemoha motsamao oa lebelo le fapaneng le theknoloji ea ho falla. Likamore tse ngata tsa khatello li sebetsa ka nako e le 'ngoe, phapang ea khatello ea khase pakeng tsa likamore tse haufi tsa khatello e nyane, ho lutla ha khase ho nyane,' me matla a molumo a phahame. Li-compressor tsa meqolo li se li sebelisoa haholo lefapheng la sehatsetsi se senyenyane ka lebaka la melemo ea tsona ea sebopeho se kopaneng, ts'ebetso e phahameng le ho boloka matla, ho sisinyeha ho tlase le lerata le tlase, le ts'epahalo ea ts'ebetso, 'me ka hona e fetohile e' ngoe ea litsela tse kholo tsa nts'etsopele ea theknoloji ea compressor.

Mafunction a tloaelehileng

E le karolo e sebetsang e potolohang ka lebelo le phahameng, compressor ea air conditioner e na le monyetla o moholo oa ho hlōleha. Liphoso tse tloaelehileng ke lerata le sa tloaelehang, ho lutla le ho se sebetse.

(1) Lerata le sa tloaelehang Ho na le mabaka a mangata a lerata le sa tloaelehang la compressor. Ka mohlala, clutch ea electromagnetic ea compressor e senyehile, kapa ka hare ho compressor e apere haholo, joalo-joalo, e ka bakang lerata le sa tloaelehang.

①Clutch ea electromagnetic ea compressor ke sebaka se tloaelehileng moo lerata le sa tloaelehang le hlahang. Hangata compressor e matha ho tloha ka lebelo le tlaase ho ea ka lebelo le phahameng tlas'a mojaro o phahameng, kahoo litlhoko tsa clutch ea motlakase li phahame haholo, 'me boemo ba ho kenya clutch ea motlakase hangata bo haufi le fatše,' me hangata bo pepesehela metsi a pula le mobu. Ha karolo ea clutch ea electromagnetic e senyeha molumo o sa tloaelehang oa etsahala.

② Ntle le bothata ba clutch ea motlakase ka boeona, ho tiea ha lebanta la li-compressor drive le hona ho ama bophelo ba clutch ea motlakase ka kotloloho. Haeba lebanta la phetiso le hlephileng haholo, clutch ea motlakase e na le monyetla oa ho thella; haeba lebanta la phetiso le le thata haholo, mojaro o ho clutch ea motlakase o tla eketseha. Ha ho tiea ha lebanta la phetisetso ho sa nepahale, compressor e ke ke ea sebetsa maemong a bobebe, mme compressor e tla senyeha ha e le boima. Ha lebanta la koloi le sebetsa, haeba pulley ea compressor le pulley ea jenereithara e se sefofaneng se le seng, e tla fokotsa bophelo ba lebanta la koloi kapa compressor.

③ Ho huloa khafetsa le ho koaloa ha clutch ea motlakase le hona ho tla baka lerata le sa tloaelehang ho compressor. Mohlala, phepelo ea matla ea jenereithara ha ea lekana, khatello ea sistimi e futhumatsang moea e phahame haholo, kapa mojaro oa enjene o moholo haholo, e leng se tla etsa hore clutch ea motlakase e hule khafetsa.

④Ho lokela ho ba le lekhalo le itseng lipakeng tsa clutch ea electromagnetic le sebaka se ntseng se hola sa compressor. Haeba lekhalo le le leholo haholo, phello e tla boela e eketsehe. Haeba lekhalo le le nyane haholo, clutch ea electromagnetic e tla kena-kenana le sebaka se ntseng se hola sa compressor nakong ea ts'ebetso. Hona hape ke sesosa se tloaelehileng sa lerata le sa tloaelehang.

⑤ Compressor e hloka lubrication e tšepahalang ha e sebetsa. Ha konpresser e haelloa ke oli e tlotsang, kapa oli e tlotsang e sa sebelisoe hantle, lerata le tebileng le sa tloaelehang le tla hlaha ka har'a kompressor, mme le be le etse hore compressor e khathale mme e hlakoloe.

(2) Leakage Refrigerant leakage ke bothata bo atileng haholo mekhoeng ea ho futhumatsa moea. Karolo e lutlang ea konpressor hangata e mateanong a compressor le liphaephe tsa khatello e phahameng le e tlase, moo hangata ho leng thata ho hlahloba ka lebaka la sebaka sa ho kenya. Khatello ea ka hare ea tsamaiso ea air-conditioning e phahame haholo, 'me ha sehatsetsi se lutla, oli ea compressor e tla lahleha, e leng se tla etsa hore tsamaiso ea air-conditioning e se ke ea sebetsa kapa compressor e se ke ea tlotsoa hantle. Ho na le li-valve tse sireletsang khatello holim'a li-compressor tsa moea. Li-valve tse sireletsang khatello hangata li sebelisoa bakeng sa tšebeliso ea nako e le 'ngoe. Ka mor'a hore khatello ea tsamaiso e phahame haholo, valve ea tšireletso ea khatello ea khatello e lokela ho nkeloa sebaka ka nako.

(3) Ho se sebetse Ho na le mabaka a mangata a etsang hore konpresser ea moea e sa sebetse, hangata ka lebaka la mathata a amanang le potoloho. U ka hlahloba esale pele hore na kompressor e senyehile ka ho fana ka matla ka kotloloho ho clutch ea electromagnetic ea compressor.

Litlhokomelo tsa tlhokomelo ea moea

Litaba tsa polokeho tseo u lokelang ho li ela hloko ha u tšoara lihatsetsi

(1) U se ke ua tšoara sehatsetsi sebakeng se koetsoeng kapa haufi le lelakabe le bulehileng;

(2) Likhalase tse sireletsang li tlameha ho roaloa;

(3) Qoba sehatsetsi se metsi se kenang mahlong kapa ho fafatsa letlalong;

(4) U se ke ua supa batho ba ka tlase ho tanka ea sehatsetsi, litanka tse ling tsa sehatsetsi li na le lisebelisoa tsa tšohanyetso tse kenang ka tlase;

(5) U se ke ua beha tanka ea sehatsetsi ka ho toba metsing a chesang a nang le mocheso o fetang 40 ° C;

6

PONTS'O RONA

Lihlahisoa tse amanang

Lihlahisoa tse amanang

-

theko ea fektheri SAIC MAXUS V80 OIL PAN C00046467

-

theko ea fektheri SAIC MAXUS V80 lipane tsa brake tse ka pele C...

-

Sefahla sa mantlha sa mofuta oa SAIC sa Front Diesel se kopanya...

-

Pompo ea mafura ea mofuta oa SAIC ea MAXUS V80 C00...

-

trunk sekwahelo poleiti bakeng sa MAXUS V80 C00001192

-

SAIC MAXUS V80 C00001525 lebanta la jenereithara